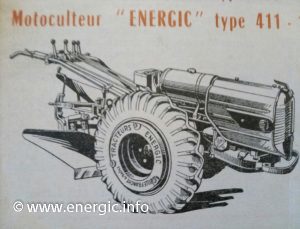

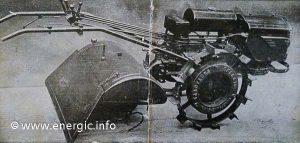

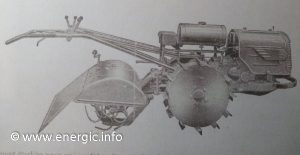

Energic motoculteur 411.

Engine/Moteur. Single-cylinder Patissier engine, 11cv, 700cm3, air-cooled, four-stroke with enclosed Lateral valves (soupapes latérales).

Lubrication. By constant circulation of oil held within the sump of the engine, 3.5 litres. The circulation pressure is attained from crankcase compression.

Cooling. One large aluminium fan is mounted at the front of the engine, running on ball bearings. This system draws air into the hood circulating around the engine, ensuring cooling. this system was tested in extremely high temperatures and proved effective.

Starting. By hand crank, either directly onto the motor, or via the multiplicator. Both located at the front of the engine.

Magneto/Magnéto. Morel CT – 1 or Lavallete, as standard equipment (also Bosch and Novi brands were used between 1945 and the 1960s to a lesser extent).

Air filter/Cleaner. Metallic element – (dependent upon the element that can be oil surface coated).

Gears. The three-speed gearbox is built within the engine offering 2 variations either 3 forward and 1 reverse or 6 forward and 3 reverse gears.

Reverse. 3 speeds are available in reverse depending upon the options. The application of reverse gear lifts the plough out of the ground. This is also used for manoeuvring the motoculteur.

Clutch. Multiple disc type immersed in oil, within the chassis casing. PTO; front (revolving at the speed of the engine), side and rear (turning between 125 and 1800 rp/m). ( PTO rear and side options).

Speeds. With 1st gear giving 1.81kmph, 2nd – 2.49kph, 3rd – 3.39kph, 4th 5.79kph, 5th 7.74kph and 6th gear giving 10.45kpm @ 2000 rpm.

Energic 411 motoculteur 11cv.

Exhaust/Silencer. Fitted in a frontal position, away from the driver.

Steering. Independent wheel clutches makes steering very easy. De-clutching one wheel, and using reverse gear allows the motoculteur to be turned in its own width without undue effort.

Energic 411 motoculteur 6 Vitesse levers + plaque.

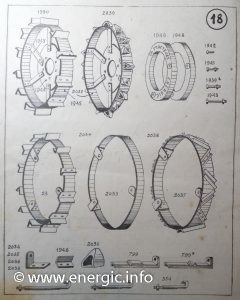

Wheels. 3 options; Pneumatic Dunlop CR Tyre wheels 750 x 18 for ploughing (labour) and 650 x 16 or T 32 for drilling ( Fraisage), metal paddle wheels and spud/rounded spikes metal wheels. (special smaller Marachère metal wheels of 50 cms could be additionally ordered for the adaption rotavator and 70 cms for ploughing). The blockage is independent for each wheel. Wheel width is regular-able between 64 cms and 85 cms in 9 settings. In metal wheels 53 cms to 83 cms.

Carburetor/Carburateur. Zenith 26 TH, standard. (later models sometimes had a Zenith 28 RXZ – first installed in the 511, 411 tracteurs and motoculteurs – as a replacement repair).

Energic Motoculteur 409 9cv Carburetor/Carburateur Type Zenith (Lyon) 26TH.

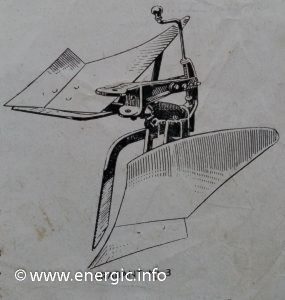

Hitch. Articulated pivoted strengthened bar, Breveté system S.G.D.G. (patented in France and the UK), with universal fitment to all ancillary equipment. Enabling the adjustment of draft and other characteristics required to operate the implements at different depths.

Ploughing depth. Up to 12 ins (30,48 cms) dependent upon soil conditions.

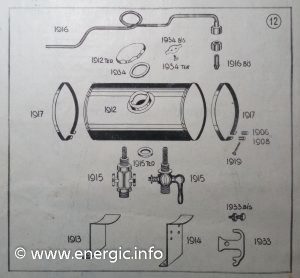

Fuel consumption. 1 1/2 to 2 litres of fuel per hour dependent upon working conditions. the tank holds approx. 9 litres.

Weight. 490kgs. Serial numbers from 11 000 to 13 500.

Optional equipment. Energic 411 models; Rotivator/Fraise, High pressure reservoir for the the treatment of fruit trees/pulvérisateur haute pression pour le traitement des arbes fruitiers. Trailer/remorquages.

PTO operating rear of the motoculteur.

***

Energic 411 model adaption options***********************

Lights – frog eye.

Energic 411 with lights – factory prototype.

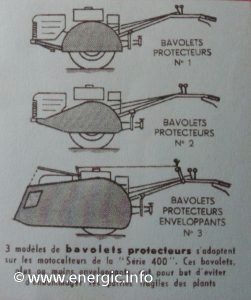

Bavolets protectors the sensible option in vineyard work.

After the war, the Energic 409 flagship motoculteur could be fitted with Bavolets for vine work (later available on the whole of the 400 series; 410, 411 and 412 motoculteurs). 3 types existed. No.1; just the wheel its self, No. 2; the leading edges on to the wheel and finally No. 3; the all-enveloping “envelopment” protector which streamlined the whole machine for easy passage through the vines and close orchard work. option 3 means that some of the lever control needed to be routed over the fuel tank.

***

Rotavator/Fraise Rotative

Rotavator/Fraise Rotative

Energic series 400 motoculteur rotivator

This adaption can be mounted quickly onto a rear PTO. The dents are 75 cms, with a width of 80 cms.

The extra weight was sometimes required in hard/compact soil to enable the rotavator to bite and not bounce on rougher surfaces.

Spraying/Pulvérisation

These high-pressure systems were used for spraying vines and fruit trees.

The system on the left-hand side (system 102) for clients with fruit trees. A tender of 200 litres, towed, operated from the PTO lateral could operate 2 lances at high pressure.

The system on the right-hand side (system 103) for clients with fruit trees and vines, is very easy to assemble and separate from the motoculteur (10 seconds was the boast from Energic). The towed unit is the sprayer and is independent when powered up from the motoculteur.

Hay/grass cutter/Fauchage.

This adaption was one previously used on animals (horses, cattle), here just supplying the pulling power with an Energic motoculteur.

Towing trailers/Remorquage

Energic 409/411 trailer/remorquage.

Energic 409/411 pulling that hay in!

Energic motoculteur abroad in Africa!

The following implements were available across the 400 series starting on the 409 of 1946 and used throughout the production history;

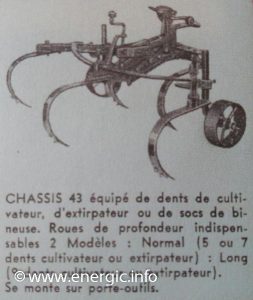

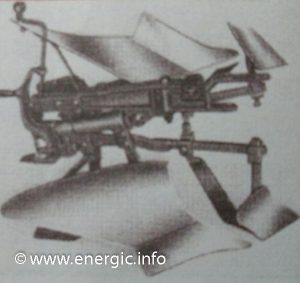

Cultivateurs/Extirpateur

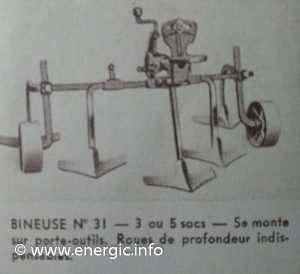

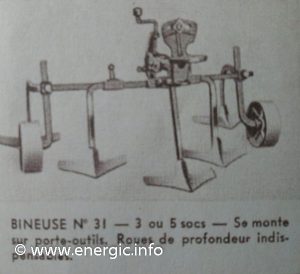

Bineuse

Buttoir

Specialist lifters and cutters.

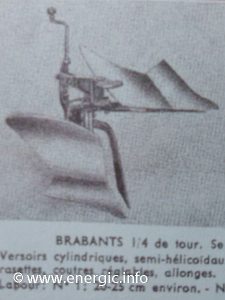

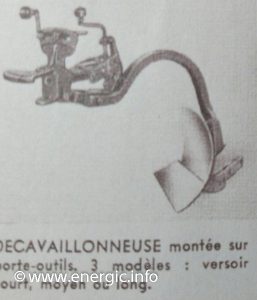

Ploughs.

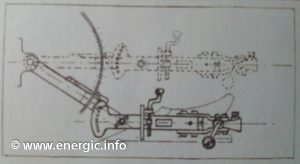

Hitches/Attachments – sulky.

Fancy an electric start.

Modified for an electric start. Just reverse the fuel tank then you have space for the battery!

Or original Dynastar set up as per 511 mark 2 modified or not!

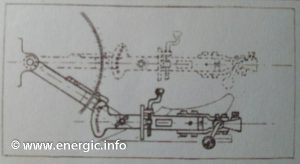

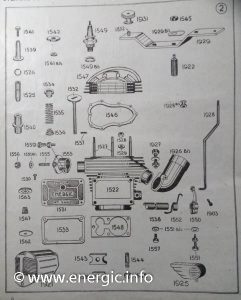

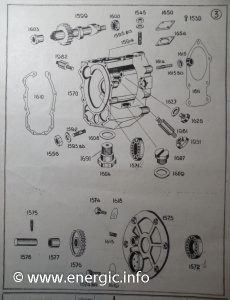

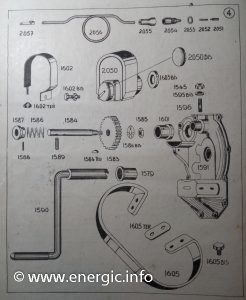

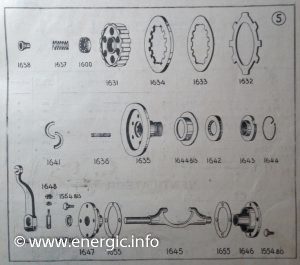

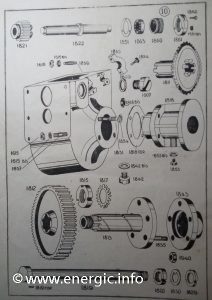

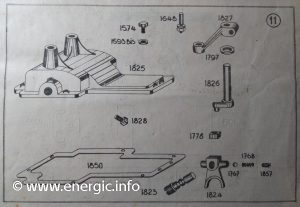

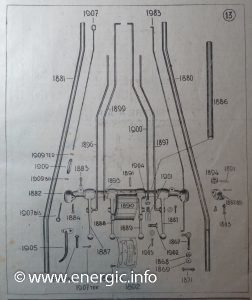

***Technical illustrations/machine breakdown from “Catalogue des pièces détachées” – parts manual***

Key;

- Embiellage, 2) Cylindre, Décompresseur, Capot, Support, Pot d’échappement, 3) Carter moteur et distribution.

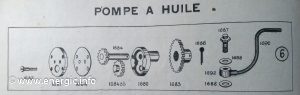

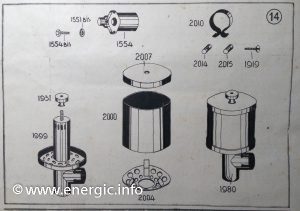

4) Carter avant, Magneto, Pares-chocs, 5) Embrayage, 6) Pompe à huile.

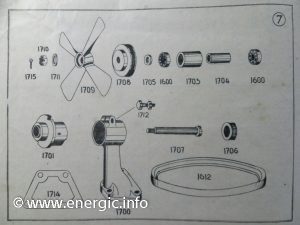

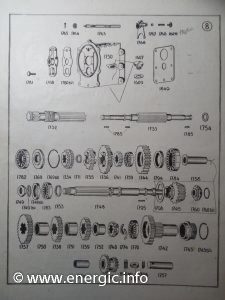

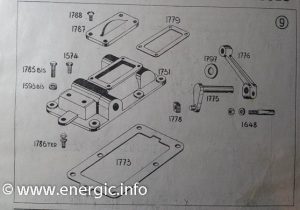

7) Ventilateur, 8) Boite des vitesses, 9) Couvercle de la boite des vitesses.

10) Pont arrière, 11) Couvercle du pont arrière, 12) Réservoir d’essence et ses supports,

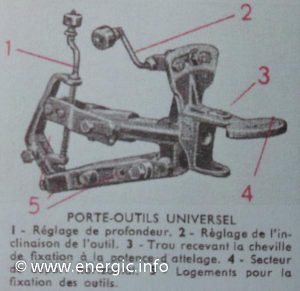

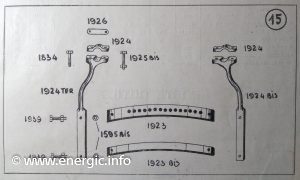

13) Mancherons et commandes,14) Filtre à air, 15) Secteur d’attelage.

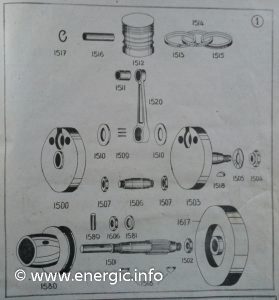

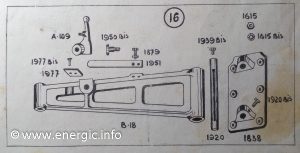

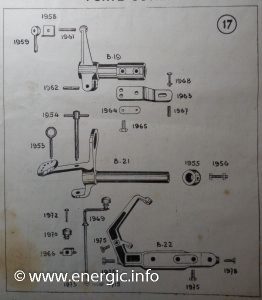

16) Potence, 17) Port-outils, 18) Roues.

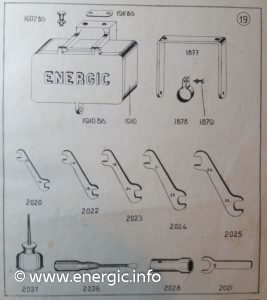

19) Coffre à outils et outillage.

********************

Energic 409/411 motoculteur hard at work in the fields!

Gallery;

**********

Read more about the Energic factory history here.

Read more about the Energic motoculteur 409 here.

Read more about the Energic Motoculteur 410 here.

Read more about the Energic motoculteur 412 here.

Read more about the Energic Engine/Moteur supplier Indenor here.

Read more about the Energic Engine/Moteur suppliers Ruggerini here.

Read more about the Energic Engine/Moteur supplier Peugeot here.

Read more about the Energic Engines/Moteurs supplier Sachs here.

See more on Facebook page: www.facebook.com/energic.info

If you like my Facebook page then I can put more information on it./ Si vous aimez ma page Facebook, je peux mettre plus d’informations à ce sujet.