Fan assembly and grease system.

The very earliest fans used on the Energic moteurs were made from a solid circular heavy plate cut and bent inwards to form a fan – on the very first B1’s (below).

Energic pressed plate on the earliest B1 models 1929/30.

To a dual pressed lighter plate operated on an axle without forced lubrication below in an Energic motoculteur B5.

Energic pressed plate 4 spoke on the earliest B5 models.

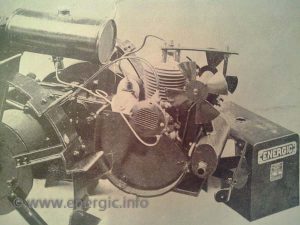

To a to a 4 spoke angled cast aluminium fan (hand finished) found on the Energic motoculteur C7 B4L, C7 S Bloc and D9 S Bloc.(lubricated by a revolving click grease reservoir cup) on a slid axle.

The aluminium fan proved effective but quite fragile and would deform easily and break when knocked as they often were. These fans with blades intact are difficult to find. Often re cast aluminium fans, were manufactured to replicate the originals but were of varying size, non uniform construction and often of different sizes. Many people improvised with alternative fan blades, from weldings to car fans.

A perfect aluminium cast fan – rare. Re cast aluminium fans not to correct size.

Yet another broken one. Hard to find – a perfect fan.

Alternative fan construction on a C7. And another! found on a D9.

lubricated by a revolving click grease reservoir cup

Grease reservoir, twist to dispense.

Internal grease cup and click stem. Rare – internal spring to click stem.

*******

Read more about Energic Wheel clutch pins here.

Read more about Energic Fan assembly and grease cups here.

Read more about Energic Motobécane engines and history here.

Read more about Energic motoculteur C7 B4L here.

Read more about Energic motoculteur D9 B5L here.

Read more about Energic motoculteur D9 S Bloc here.

Read more about Energic motoculteur C7 S Bloc here.

Read more about Energic History here.

See more on Facebook page: www.facebook.com/energic.info

If you like my Facebook page then I can put more information on it./ Si vous aimez ma page Facebook, je peux mettre plus d’informations à ce sujet.