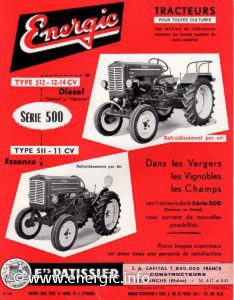

Energic tracteur mark 2 after 1954/5.

Energic brochure 500 series showing 511 tracteur mark 2 1955+

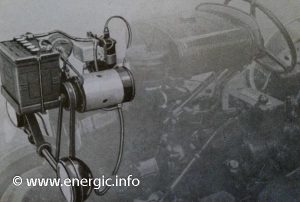

Engine. Single-cylinder Patissier engine, petrol (essence), 11cv, 700cm3, Alésage x course : 95 mm x 98 mm, air-cooled, four-stroke with enclosed Lateral valves. The cylinder head is made from special aluminium.

(Soupapes latérales inclinéees, embiellage monté sur de forts roulements à galets, tête de bielle cémentée et rectifiée tournant sur de forts roulements à aiguilles). Culasse en alliage spécial d’aluminium.

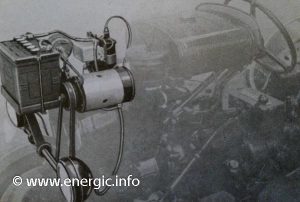

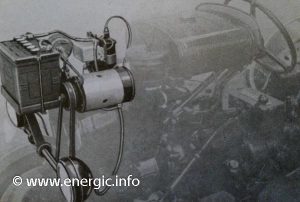

Energic 511 tracteur mark 2 engine/moteur 11cv.

Energic 511 tracteur mark 2 engine/moteur 11cv.

Energic 511 tracteur mark 2 engine/moteur 11cv The fan should be cast aluminium.

Energic tracteur 511 petrol engine righthand view engine.

Energic Tracteur 511 mark 2 engine.

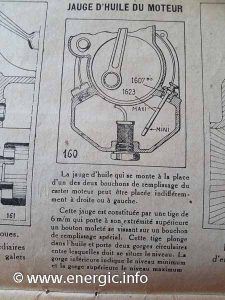

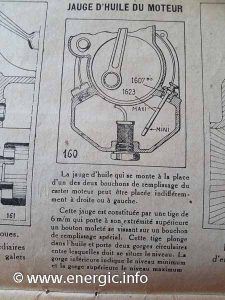

Lubrication. By constant circulation of oil held within the sump of the engine, 3.5 litres. The circulation by pumped pressure also from crankcase compression. (Graissage par pompe incorporée).

Cooling. One large aluminium fan is mounted at the front of the engine, running on ball bearings. This system draws air into the hood circulating around the engine, ensuring cooling. this system was tested in extremely high temperatures and proved effective. (Refroidissement par air forcé (ventilateur puissant).

Starting. By hand crank, either directly on to the motor, or via the multiplicator. Both located at the front of the engine.

Energic tracteur 511 petrol electrics.

Air filter/Cleaner. Metallic element – (dependent upon the element that can be oil surface coated).

Steering. By worm gear.

Carburateur. Zénith with lever for easier starting. in the cold.( Zénith tous terrains, avec volet d’air pour départs à froid).

Gears. The three-speed gear box is built within the engine offering 2 variations either 3 forward and 1 reverse or 6 forward and 3 reverse gears. At extra cost, you could buy a reducer gearbox that would allow you 12 gears/speeds instead of 6. This gives you more options for fast/rampantes, normal/normal, slow/lentes – for road work to grass cutting. Effectively a 6 speeds rapid and 6 speed slow/lente.

Differential. Blockable

Speeds. 1st gear 2 kmh, 2nd gear 3 kmh, 3rd gear 4 kmh, 4th gear 7 kmh, 5th gear 12 kmh, 6th gear 18 kmh with gearbox box “C”.

PTO/Prise de force. Located at the rear of the tracteur. Available in all 6 gears.

Reverse. 3 speeds are available in reverse depending upon the options.

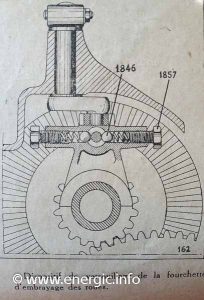

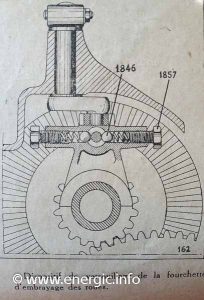

Clutch. Multiple disc type immersed in oil, within the chassis casing. PTO; front (revolving at the speed of the engine), side and rear (turning between 125 and 1800 rp/m). Clutch engagement for the PTO systems. ( PTO rear and side options).Embrayage est du type à disques multiples baignat dans l’huile.

Exhaust/Silencer. Fitted in a frontal position, away from the driver.

Magneto. Either Morel or Lavalette type. (Allumage par magnéto à déclic, assurant un démarrage instantanné).

Wheels. 3 options; Pneumatic Tyre wheels front 400 x 15 and 750 x 18 Rear (Dunlop T 32 or Michelin type CR for ploughing). Or at extra cost tyres 8 x 24 depending upon the adherence to the soil required. Blockage is independent for each wheel. Wheel width is regular-able in 9 stages between 0.53m and 1.15m. These widths are obtained by altering the wheels into different positions.

Brakes. On each rear wheel shoe type, pressure by manual foot pedals, independent that can be linked.

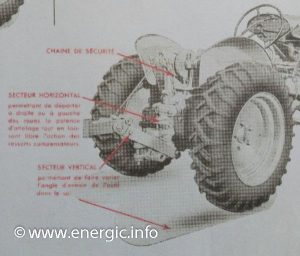

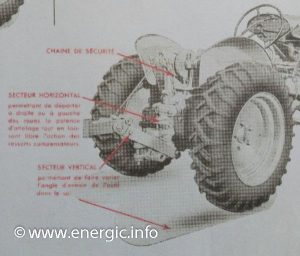

Hitch. See below. 3 options Type B – manual, type A Dynabloc automatic and type C – Dynabloc hydraulic 3-point lift. Breveté system S.G.D.G. (patented in France and the UK) articulated strengthened with universal fitment to all ancillary equipment. Enabling the adjustment of draft and other characteristics required to operate the implements at different depths. The Dynabloc automatic was tested for some 200 000 lifts of 250kgs, without loss of lift capability.

Ploughing depth. Up to 12 ins (30,48 cms) dependent upon soil conditions.

Fuel consumption. 1 1/4 to 2 litres of fuel per hour dependent upon working conditions. the tank holds approx.17 liters.(Réservoir de carburant).

Weight. Really depends on the tracteur set up. An example a tracteur with 8 x 24 tyres + Type B attelage = 785kgs. with tyres full of water + 78 kgs and metal wheel weights + 92 kgs. = 955 kgs. If you added a dynabloc 3 point hydraulic hitch then the weight would go up still further to near a ton. It depends how you set the tracteur up for ploughing more weight and for lighter spraying (without 200 litres of fluid) – a lot less.

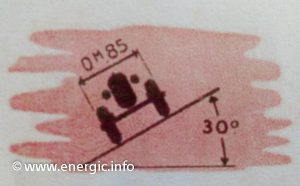

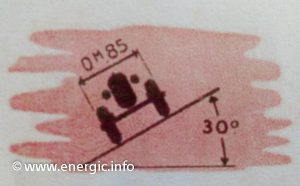

Turning circle/Angle of safe working. 1.80m, it was able to operate safely at a maximum angle of 30 degrees at a width of 0.85 m.

Dimensions. Length 2.3 m, width 0.85 m (85 cm, 90 cms, 95 cms, 100 cms, 105 cms, 110 cms and 115cms), height to seat 75cms and height to steering wheel 1.2m. (Longueur totale 2.3 m, Largeur de 0.85 m, à 1.2 m Hauteur au volant). These are different to the Energic 511 Mark 1 tracteurs just by minimum amounts; length + 10 cms height at steering wheel + 5cms and so on.

Narrow width/Vigneron formation, as narrow as 0.85m!

Energic brochure 500 series showing 511 tracteur mark 2 1955+.

****Optional equipment/adaptions**** Energic 500 series models at extra cost;

Electric pack; Starter – Dynastar with batterie 12v 30amps/hour with regulator. Operating lights, front and rear, brake lights, plug for trailer/remorque,side lights and horn.

Energic 511 tracteur mark 2 electric Dynastar electric pack.

PTO/Prise de force. Costs extra for all 500 eries tracteurs. The rotation speed of the PTO/Prise de force (with Dynabloc) ; with the moteur rotating at 2000 rpm is; 1st gear 250 tr/mn., 2nd gear 345 tr/mn., 3rd gear 500 tr/mn., 4th gear 700 tr/mn., 5th gear 1000 tr/mn., 6th gear 1440 tr/mn.

Other options include; 3 point lift hydraulic Dynabloc, rotivator/fraise, high pressure reservoir for the the treatment of fruit trees/pulvérisateur (haute pression pour le traitement des arbes fruitiers). Trailer/remorquages. Wheel weights. Poulies diameter 180mm offering adaption perpendicular to the PTO. Hoe/cultivateur special 10 dents. Winch.

Energic 511 tracteur mark 2 demonstration work 1961.

Energic tracteur mark 2 demonstrations ploughing 1961.

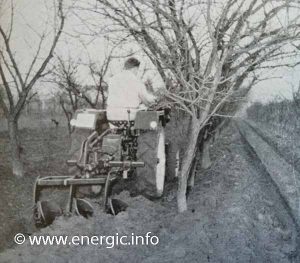

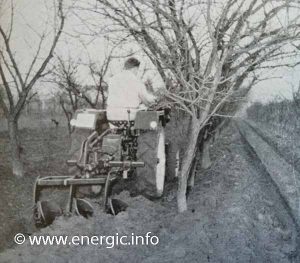

Energic 511 tracteur mark 2 demonstration hoeing in the fruit trees 1960’s.

Energic 511 tracteur mark 2 canadien

Energic 511 tracteur mark 2 canadien

Energic large machine stand showcasing tracteur range May 1960.

Energic Agricole show 1958 with Mr A Patissier presenting on the stand.

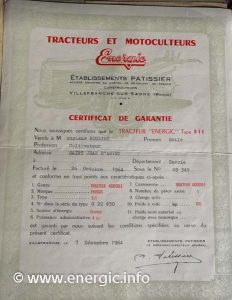

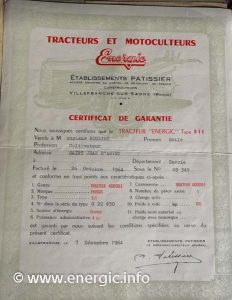

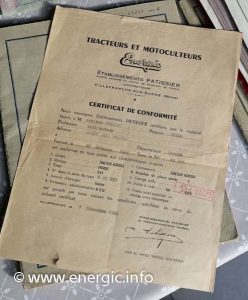

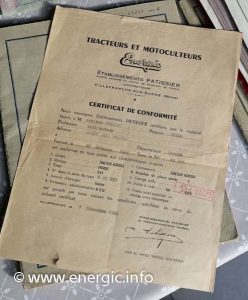

Certificate of conformity;

Driving is child’s play, energic 511 mk2.

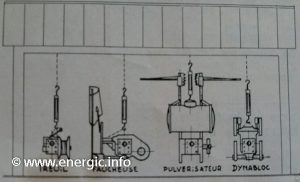

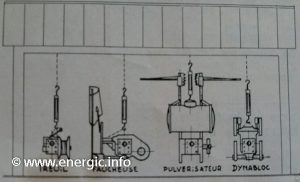

****Mounting adaptions****

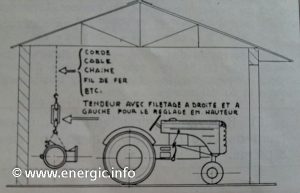

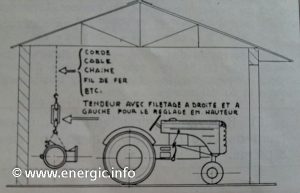

Treuil, Faucheuse, Pulverisateur and Dynabloc. By the use of a crane or block and tackle lift and reversing the tracteur into position for mounting the adaptions/outils.

Snow plough!

adaption artisanal.

****Ploughs/charrues**** Brabant mono soc 1/4 turn versions cylindrical x 2 (25 and 30 cms), version 1/2 helicoidaux (20 cms) and other variations see below.

Energic tracteur 511 petrol with charrue brabant monosoc.

Bi-soc No 63 angled non-reversible plough. With 2 positions for the blades either normal or décvaillonneur.Also available in many models adapted for the type of agricultural requirement. such as the depth of plough, 25 or 30 cms. Types including Bec de Canard, soc ordinaire. Décavaillonneur for work on plantations etc.

Energic tracteur 511 one soc.

Energic tracteur 511 one soc

Tri-soc No 68/ No 63 angled non-reversible plough. With 2 positions for the blades either normal or décvaillonneur.

3 soc/corps mounted on a chassis plough for vine work/viticulture

****Plough Brabant 1/2 turn/tour****

Brabant 1/2 turn 12 inches, Energic manufactured with regularable width, depth of cut. It is necessary to alter the wheelbase/width of the tracteur to facilitate this larger plough. Here illustrated on a 512 tracteur. Brabants 1/4 turn is available in 25 cms and 30 cms plough depth forms in cylindriques. Brabants are also availlable in1/4 turn 25 cmsand 30 cms plough depth forms in Hélicoidaux (soc rocheux). Upon demand they can be bought in allonges de versoirs, bec de canard, rasettes, pleine soc, porte socs etc.

Energic 511 mark 2 internal ploughs/adaptions.

****Potatoe lifter****

****Hoes/Bineuse****

Hoe 5 socs on a chassis No 43. Chassis No 43 consists of a frame in the shape of a V, which is variable in width depending upon the use. Normal with 5 or 7 dents or long with 9 dents. It also can be used as a Cultivateur with 5, 7 or 9 dents that are semi-rigid. Or an Expirpateur the same with dents rigid. In the form of a Bineuse it would have 3 or 5 socs in normal form and 7 socs in long-form. The wheels can be altered to height or removed.

****Cultivateur****

The first photo shows a smaller rear only positioned cultivateur that can be lifted when not in use. The other 9 or 10 dents with supporting wheels. For working on plantations or and full/only soil. The whole width of the tracteur is worked. Operated at slower speeds in plantations.

****Hay/grass cutters****

512 diesel with the rear cutter.

Available as are retrofit in 2 positions, lateral or rear behind dynabloc or the PTO. It was regulable for height and angle. With 3 models available Normale, Danoise and Intermediate. The blades were easily changed for maintenance or in case of breakage/replacement. The cutter/barre de coupe blade being 1.37m in width. Fitted to the 511 and 512 series.

****Rotivators/Cultivateur rotatif****

Branded Energic “Rotener”, patented S.G.D.G. for tracteurs with fast gearing. It was adapted to go behind the Dynabloc’s PTO/prise de force. It was designed to condition the soil by rotating on its axis with power directly from the rear PTO. The depth of rotative penetration was automatic, with the width being regulated between 1 m and 1.20 m.

****Rear PTO output****

The PTO/prise de force can operate a pulley wheel of various diameters from 110 mm, 150 mm, 180 mm, to 210 mm. This system can operate external large equipment like combines/moissonneuse, manure distributors/ epandeur de fumier, cutting bars/barre de coupe etc., It can be operated through 6 speeds/gears and is operated stationary for pumps, saws, threshers etc. This PTO box pulley system is attached by 6 screws and can easily be placed or detached.

****Spraying system/Pulvérisateur****

Maximum capacity of 200 litres, for the treatment of trees, shrubs, vines, fruit trees in all forms of agriculture large to small. The sprayer operates from 0 to 40 kg/cm2 pressure (3 pistons). This can be regulated depending upon the usage, treatment and product. It is operated directly from the PTO/prise de force and can be sprayed through up to 3 lances.

****Rear lifts options*****

Energic Tracteur 511 mark 2 Dynabloc. www.energic.info

Type A Dynabloc automatic. Low maintenance, lifting capacity of 250 kgs, The PTO/prise de force comes out of the back of the Dynabloc system when lifted out of the way. You can either tow from the chap/crochet on the dynabloc or the bar de outils. this system could be fitted to a narrow width of 511/2 as shown in the photo above. (Attelage type S)

Type B manual lift. Operated with a lever system pulling through gears and ratcheting a cable to raise the towing hook for the ploughs etc. You could either pull the implements/outils directly behind the tracteur or set them at an angle to suit the type of agriculture, viticulture you were operating in.

Type C hydraulic lift/revelage hydraulique. Using a 3 point system – operating through the pressure of oil through the Dynabloc, that can be infinitely variable for height and pressure.

****Winch/Treuil****

Model B from 1953 fitted with a winch/treuil option. (steel cable 100, 150 and 200 meters in length). The winch could be operated at 6 speeds. It was primary used in the following conditions; when the soil is very heavy (clay-based), when cutting the earth was impossible with a pulled plough, when pulling very heavy loads/logs. The winch pulley pulls the cable from the side. It could be fitted with other ancillary equipment modified for specific use. Also, you could attach a hook/bar for towing.

Energic tracteur 511 petrol with treuil.

Rear PTO;

Energic tracteur 511 petrol with rear PTO. www.energic.info

****Towing/Remorquage****

Energic tracteur 511 mark 1, pulling a large agricultural trailer/remorque.

The series 500 tracteurs could pull up to 3 tonnes, as long as the trailer/remorque had good brakes!

****

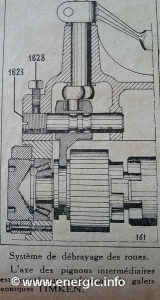

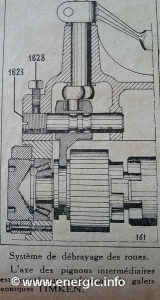

System de débrayage des roues et jauge d’huile du moteur.

Gallery;

Oddball with front lift;

***********

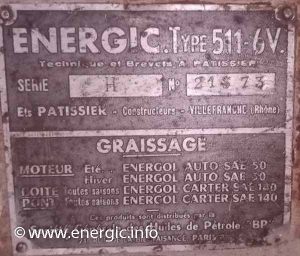

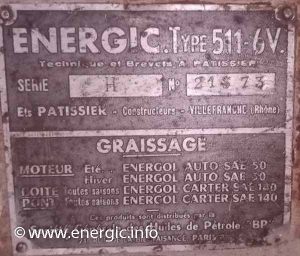

Plaques;

Energic Tracteur 511 mark 2 plaque positioning. www.energic.info

***

*******

Read more about Energic 511 Mark 1 tracteur here.

***

Read more about Energic 518 tracteur here.

Read more about Energic 519 tracteur here.

Read more Energic Engine/Moteur supplier Indenor here.

Read more about Energic Engine/Moteur supplier Peugeot here.

Read more about Energic Sachs Engines/Moteurs here.

See more on Facebook page: www.facebook.com/energic.info

If you like my Facebook page then I can put more information on it./ Si vous aimez ma page Facebook, je peux mettre plus d’informations à ce sujet.