Energic 411 Winch/Treuil.

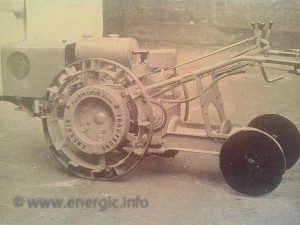

In the left-hand photo, you can see the heavy-duty correction screw system, which gave extra stability when winching.

The winch adaption was a excellent alternative to the motoculteur and the plow, when faced with difficult demanding terrain. Such as very steep slopes. With 9 speeds in a reinforced structure, the winch’s power could plough to depths of 50cm! the Treuil system could be mounted on to the PTO box within minutes. The position or the winch could be easily adjusted by the use of the correction screw system, with narrow wheels that gripped the terrain. This enabled smooth rewinding of the steel cable on to the revolving barrel.

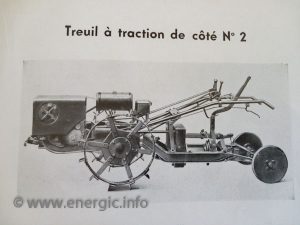

Energic 411 Treuil/winch brochure.

Energic S bloc Treuil/winch, model before the 411.

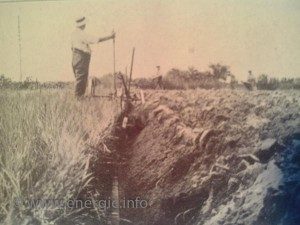

Energic Treuil/winch deep furrow/plough.

The new adaption system of the 409/411 was different to the separate model system on the older C7 and D9 winches, with their over-specification of components to cope with the riggers and stresses involved in winch work up to 250m away. See below the old winch system on an Energic C7.

Engine. Single-cylinder Patissier engine, 11cv, 700cm3, air-cooled, four-stroke with enclosed Lateral valves (soupapes latérales).

Lubrication. By constant circulation of oil held within the sump of the engine, 3.5 litres. The circulation pressure is attained from crankcase compression.

Cooling. One large aluminium fan is mounted at the front of the engine, running on ball bearings. This system draws air into the hood circulating around the engine, ensuring cooling. this system was tested in extremely high temperatures and proved effective.

Carburetor/Carburateur. Zenith 26 TH, standard. (later models sometimes had a Zenith 28 RXZ – first installed in the 511, 411 tracteurs and motoculteurs after 1954/5 – as a replacement repair).

Energic Motoculteur 409 9cv Carburetor/Carburateur Type Zenith (Lyon) 26TH.

Starting. By hand crank, either direct on to the motor, or via the multiplicator. Both located at the front of the engine.

Magneto/Magnéto. Morel CT – 1 or Lavallete, as standard equipment (also Bosch and Novi brands were used between 1945 and the 1960s to a lesser extent).

Air filter/Cleaner. Metallic element – (dependent upon the element that can be oil surface coated).

Gears. The three-speed gearbox is built within the engine offering 2 variations either 3 forward and 1 reverse or 6 forward and 3 reverse gears.

Reverse. 3 speeds are available in reverse depending upon the options. The application of reverse gear lifts the plough out of the ground. This is also used for manoeuvring the motoculteur.

Clutch. Multiple disc type immersed in oil, within the chassis casing. PTO; front (revolving at the speed of the engine), side and rear (turning between 125 and 1800 rp/m). ( PTO rear and side options).

Energic Treuil/winch 411 in action.

Exhaust/Silencer. Fitted in a frontal position, away from the driver.

Steering. Independent wheel clutches make steering very easy. De-clutching one wheel, and using reverse gear allows the motoculteur to be turned in its own width without undue effort.

Wheels. 3 options; Pneumatic Tyre wheels 750 x 18 front, metal paddle wheels and spud/rounded spikes metal wheels. (special smaller Marachère metal wheels of 50cms could be additionally ordered for the adaption rotavator). Blockage is independent for each wheel. Wheel width is regular-able in 9 stages between 0.53m and 1.15m. These widths are obtained by altering the wheels into different positions.

Ploughing depth. Up to 50cms.

Fuel consumption. 1 1/2 to 2 litres of fuel per hour dependent upon working conditions. the tank holds approx. 9 litres.

Weight. 500+kgs.

Energic Treuil/winch 409/411.

Energic Treuil/winch 411. metal wheel option.

*******

Read more about the Energic factory history here.

Read more about the Energic motoculteur 409 here.

Read more about the Energic motoculteur 411 here.

Read more about the Energic 412 motoculteur here.

See more on Facebook page: www.facebook.com/energic.info

If you like my Facebook page then I can put more information on it./ Si vous aimez ma page Facebook, je peux mettre plus d’informations à ce sujet.